As you guys may or may not know, my kayak (OK Torque) is recommended to be powered with a 12v, group 24 deep cycle battery. While this powers the kayak just fine and dandy, transporting this class of battery can be a pain in the butt at times. A group 24 battery will weigh in the 50lb range. My current unit weighs 53lbs to be exact. I was able to manage just fine, but I wanted something lighter without sacrificing power capacity. I began researching lithium ion battery solutions. I've spent countless hours of reading thread after thread on various electric vehicle and electric bike message boards...also gained useful information from sailboat forums.

I found a website where I could order a 60aH 12v LiFePO4 (lithium iron phosphate) battery pre-assembled and ready to go, weighing a mere 20lbs. This battery cost $569, not including shipping. Definitely not for the faint of heart or wallet. I wanted a cheaper solution. I began research on building my own lithium battery.

I went through plenty of email conversations with people from china, representing various battery manufacturers. All of the LiFePO4 cells come from china. I figured I'd explore the option of buying direct. This was difficult...downright frustrating at times. The time difference made timely correspondence difficult. The language barrier made emails hard to comprehend. And overall was the trust factor. Every question I asked was pretty much responded to with " yes, no problem. We can make for you." Buying direct from manufacturers is catered to distributors, not single item consumers. So finding a supplier to sell a single battery was one hurdle to jump. Even still, shipping from china is a killer...both in cost and time. I'm talking like a few months from some suppliers. These transactions mostly require you setting up a bank/wire transfer...ehhh. I decided to search domestically.

After thoroughly researching which brand to buy (ThunderSky), I decided to risk the purchase through a guy/company in San Fancisco. Www.alliancerenewableenergy.com. I did some online researching about this company, with mixed results...but I gave it a shot anyways. Although it took longer than it should have (with horrible communication on their behalf) I got my product after mailing them a certified check.

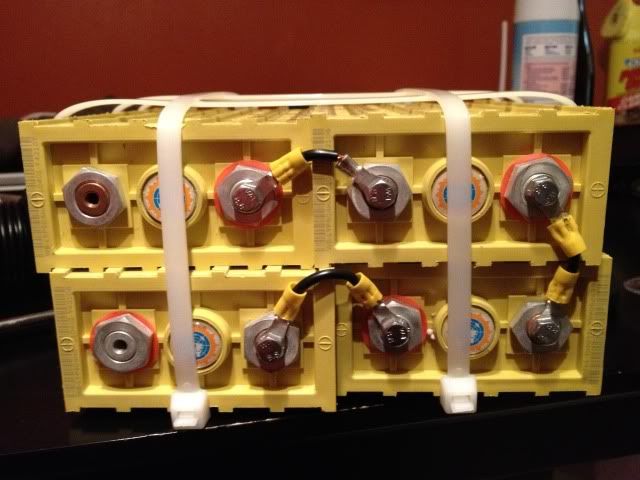

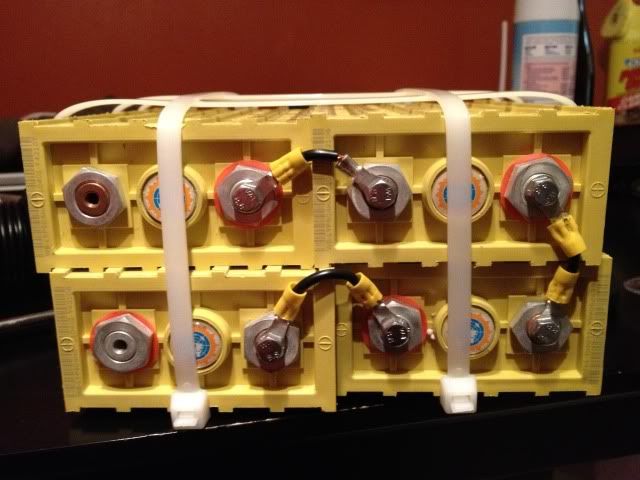

Assembling the pack was rather straight forward. I wired the four cells in series (3.2v each). I got my battery terminal bolts and other connectors from both radio shack and the local hardware stores. I secured the cells together using heavy duty zip ties. I wanted something that allowed me to easily swap out a cell should I need to do so.

Since lithium batteries are sensitive to being over discharged, I wired up a control board that is designed to protect the cells.

This circuit board protects the battery pack from over discharge by cutting power once it reaches 9.2v. It also protects it from overdrawn current...it'll shut down if it senses a 30amp draw. The torque motor pulls 25a max at full power. I got everything all soldered up, and I used Andersen PowerPole connectors for all of my wire connections. These connectors are great. I also installed a Doc Wattson meter, which tells me pertinent information such as amp-hrs used, current load, and pattern charge that I have remaining.

Before hitting the water, I did a test on land. I was testing. Both the battery, as well as my newly installed/upgraded/relocated trolling motor plug (Marinco). It worked out just fine.

http://youtu.be/nVyReEDQuG8

Excited to have my battery constructed...and my trolling motor plug replaced, I was ready to get on the water. Wanting to explore water closer to home, I went to launch at a local spot on Jam 16th...only to find THIS

Not only was the ramp iced over, but the river had a good bit of ice too. I opted to delay my testing. I was finally able to give it another shot on Sunday afternoon. The video below shows my trials...

http://youtu.be/cT_Jw74WQ2Q (2:26 is when I realized something was wrong...)

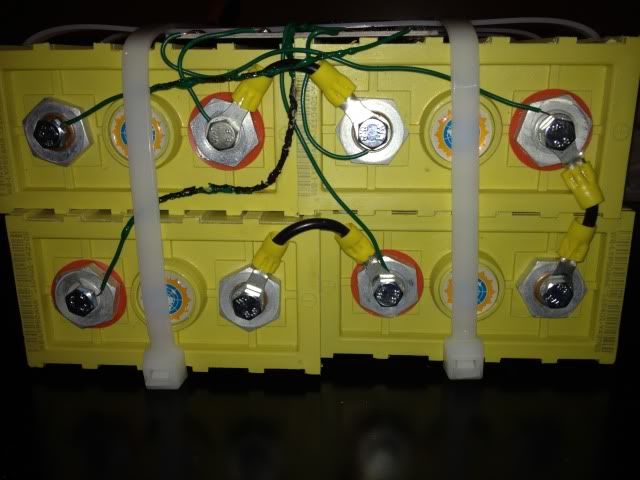

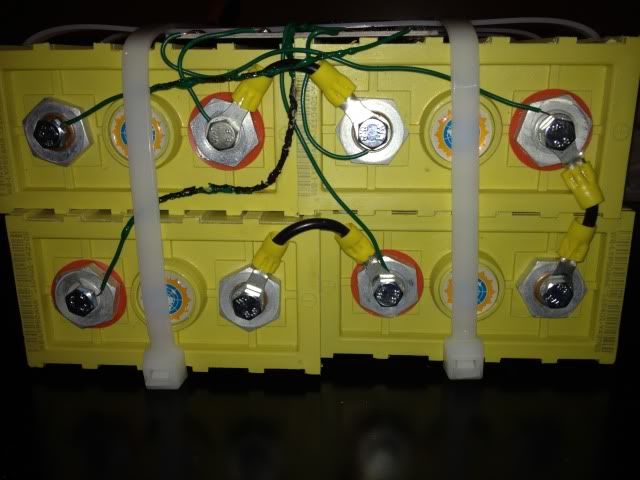

When I spoke to the vendor of my lil circuit board back in the planning phases, I asked him what gauge wire I needed to go to the individual cells. He said small, 14ga wire would be fine. I mistakenly used this small gauge wire to the pos & neg outputs from the battery pack. Once the juice got flowing, the heat generated burned the insulation. Notice the look on my face when I realized something was wrong. Notice the two [now] black wires in the pic below...

Oops. I redid the wiring that night with 10ga wires, which is originally used throughout the system. I was able to get out on the water yesterday...

http://youtu.be/sosDSYALxcM

I found a website where I could order a 60aH 12v LiFePO4 (lithium iron phosphate) battery pre-assembled and ready to go, weighing a mere 20lbs. This battery cost $569, not including shipping. Definitely not for the faint of heart or wallet. I wanted a cheaper solution. I began research on building my own lithium battery.

I went through plenty of email conversations with people from china, representing various battery manufacturers. All of the LiFePO4 cells come from china. I figured I'd explore the option of buying direct. This was difficult...downright frustrating at times. The time difference made timely correspondence difficult. The language barrier made emails hard to comprehend. And overall was the trust factor. Every question I asked was pretty much responded to with " yes, no problem. We can make for you." Buying direct from manufacturers is catered to distributors, not single item consumers. So finding a supplier to sell a single battery was one hurdle to jump. Even still, shipping from china is a killer...both in cost and time. I'm talking like a few months from some suppliers. These transactions mostly require you setting up a bank/wire transfer...ehhh. I decided to search domestically.

After thoroughly researching which brand to buy (ThunderSky), I decided to risk the purchase through a guy/company in San Fancisco. Www.alliancerenewableenergy.com. I did some online researching about this company, with mixed results...but I gave it a shot anyways. Although it took longer than it should have (with horrible communication on their behalf) I got my product after mailing them a certified check.

Assembling the pack was rather straight forward. I wired the four cells in series (3.2v each). I got my battery terminal bolts and other connectors from both radio shack and the local hardware stores. I secured the cells together using heavy duty zip ties. I wanted something that allowed me to easily swap out a cell should I need to do so.

Since lithium batteries are sensitive to being over discharged, I wired up a control board that is designed to protect the cells.

This circuit board protects the battery pack from over discharge by cutting power once it reaches 9.2v. It also protects it from overdrawn current...it'll shut down if it senses a 30amp draw. The torque motor pulls 25a max at full power. I got everything all soldered up, and I used Andersen PowerPole connectors for all of my wire connections. These connectors are great. I also installed a Doc Wattson meter, which tells me pertinent information such as amp-hrs used, current load, and pattern charge that I have remaining.

Before hitting the water, I did a test on land. I was testing. Both the battery, as well as my newly installed/upgraded/relocated trolling motor plug (Marinco). It worked out just fine.

http://youtu.be/nVyReEDQuG8

Excited to have my battery constructed...and my trolling motor plug replaced, I was ready to get on the water. Wanting to explore water closer to home, I went to launch at a local spot on Jam 16th...only to find THIS

Not only was the ramp iced over, but the river had a good bit of ice too. I opted to delay my testing. I was finally able to give it another shot on Sunday afternoon. The video below shows my trials...

http://youtu.be/cT_Jw74WQ2Q (2:26 is when I realized something was wrong...)

When I spoke to the vendor of my lil circuit board back in the planning phases, I asked him what gauge wire I needed to go to the individual cells. He said small, 14ga wire would be fine. I mistakenly used this small gauge wire to the pos & neg outputs from the battery pack. Once the juice got flowing, the heat generated burned the insulation. Notice the look on my face when I realized something was wrong. Notice the two [now] black wires in the pic below...

Oops. I redid the wiring that night with 10ga wires, which is originally used throughout the system. I was able to get out on the water yesterday...

http://youtu.be/sosDSYALxcM

Comment