I usually use a key ring velcro-ed just above the front grip on my rods for security when they are in the holder. This works well for the most part but occasionally when casting the line will foul on the ring and it makes me want to come up with a different solution. I saw something similar at Jamaica Bay a few years ago and today I decided to try it out. I'm not sure how this will work when the rod is in the holder, but we'll see.

Parts:

100lb mono

XPS ProWrap (not needed) (http://www.basspro.com/Bass-Pro-Shop...t/94037/100827)

Rubber Cap

Drill

SS washer that fits in the rubber cap and has a small opening to keep the mono in

5 min epoxy

Rod (BPS Musky 7ft MH)

Step 1 (optional)- follow the steps to install the XPS ProWrap. I choose to wrap the butt section only and my decision was based around almost loosing a rod in the ships last year togging because my hands were cold and slippery. This rod will be used for tog/heavier fish so I wanted the extra grip without the loss of sensitivity in the foregrip.

Step 2- Drill a hole in the bottom of the rod butt.

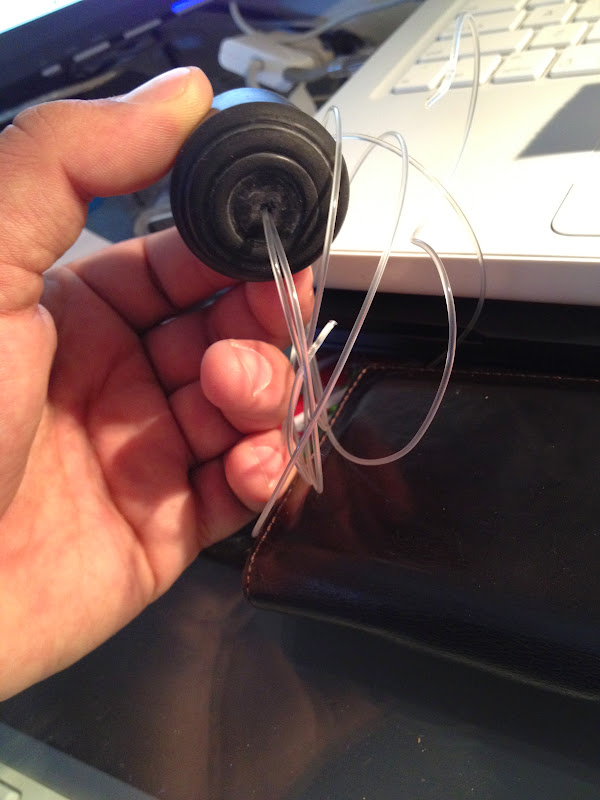

Step 3- Poke hole in middle of rubber cap and thread mono through

Step 4- Determine how large you want your loop to be. Then slide washer over the two ends, and make knot. Use something on the other side to make sure you don't pull the mono through. Try to leave the loop long enough so that you can push the knot into the butt of the rod.

Step 5- Test to make sure the knot will fit into the hole you drilled into the bottom of the rod butt and that you are comfortable with the length of the loop.

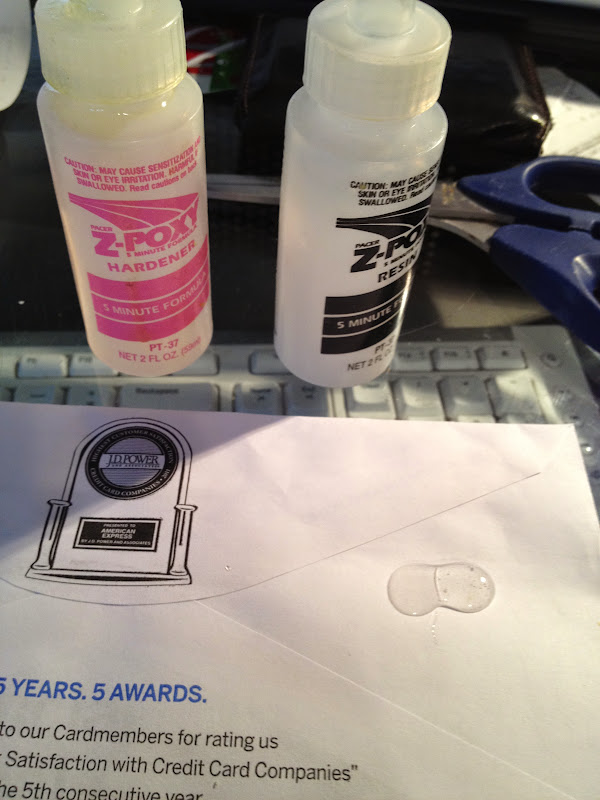

Step 6- Mix epoxy and apply to hole and knot

Step 7- Stuff knot into the rod hole and then carefully push the end cap on. You'll want to wet the end cap (spit works) and use some finesse to pull the loop out of the rubber cap as you push it on.

Step 8- Let it dry and you're ready to rock.

Parts:

100lb mono

XPS ProWrap (not needed) (http://www.basspro.com/Bass-Pro-Shop...t/94037/100827)

Rubber Cap

Drill

SS washer that fits in the rubber cap and has a small opening to keep the mono in

5 min epoxy

Rod (BPS Musky 7ft MH)

Step 1 (optional)- follow the steps to install the XPS ProWrap. I choose to wrap the butt section only and my decision was based around almost loosing a rod in the ships last year togging because my hands were cold and slippery. This rod will be used for tog/heavier fish so I wanted the extra grip without the loss of sensitivity in the foregrip.

Step 2- Drill a hole in the bottom of the rod butt.

Step 3- Poke hole in middle of rubber cap and thread mono through

Step 4- Determine how large you want your loop to be. Then slide washer over the two ends, and make knot. Use something on the other side to make sure you don't pull the mono through. Try to leave the loop long enough so that you can push the knot into the butt of the rod.

Step 5- Test to make sure the knot will fit into the hole you drilled into the bottom of the rod butt and that you are comfortable with the length of the loop.

Step 6- Mix epoxy and apply to hole and knot

Step 7- Stuff knot into the rod hole and then carefully push the end cap on. You'll want to wet the end cap (spit works) and use some finesse to pull the loop out of the rubber cap as you push it on.

Step 8- Let it dry and you're ready to rock.

Comment